Auto Testing equipment CRS-618C diesel fuel injection pump test bench optional add EUI/EUP,

COMMON RAIL test bench, test bench, testing equipment,

CRS-708C test bench is special device to test the performance of high-pressure common rail pump and injector, it can test common rail pump, injector of BOSCH, DENSO, DELPHI, SIEMENS and piezo injector. And on this basis, it also can be mounted with optional EUI/EUP test system, CAT HEUI test system. It simulates the injection principle of common rail motor completely. High output torque, ultra low noise. It tests the common rail injector and pump by flow meter sensor with more precise and stable measurement. Pump speed, injection pulse width, oil measurement and rail pressure are all controlled by industrial computer by real time. It contains more than 2000 kinds of data by computer. 19” LCD screen display makes the data more clear. Advanced technology, steady performance, precise measurement and convenient operation.

CRS-708C can fulfill the remote assistance by internet and make the maintenance easy to operate.

Feature

1.Main drive adopts the speed change by frequency change.

2.Controlled by industrial computer in real time, Windows operating system.Fulfill the remote assistance by internet and make the maintenance easy to operate.

3.Oil quantity is measured by flowmeter sensor and displayed on 19” LCD .

4.Percentage of drive signal can be adjusted.

5.BOSCH original rail, DRV to control rail pressure which can be tested in real time and controlled automatically. It contains the high-pressure protection function.

6.Oil temperature is controlled by forced-cooling system.

7.Pulse width of the injector drive signal can be adjusted.

8.Protection function of short-circuit.

9.Plexiglass protective door, easy operation, safe protection.

Function

1.common rail pump test

(1).test brands:BOSCH, DENSO, DELPHI, SIEMENS.

(2).test the sealing of common rail pump.

(3).test the internal pressure of common rail pump.

(4).test the proportional electromagnetic valve of common rail pump.

(5).test the input pressure of common rail pump.

(6).test the flux of common rail pump.

(7).measure the rail pressure in real time.

2.common rail injector test

(1).test brands:BOSCH, DENSO , DELPHI,SIEMENS, piezo injector.

(2).test the sealing of common rail injector.

(3).test the pre-injection of high-pressure common rail injector.

(4).test the max. oil quantity of high-pressure common rail injector.

(5).test the cranking oil quantity of high-pressure common rail injector.

(6).test the average oil quantity of high-pressure common rail injector.

(7).test the backflow oil quantity of high-pressure common rail injector.

(8).Data can be searched, saved and made into database.

3.EUI/EUP test (optional)

4.CATHEUI test (optional)

Technical Parameter

1.Pulse width: 0.1-5ms;

2.Fuel temperature: 40±2℃;

3.Rail pressure: 0-2500 bar;

4.Test oil filtered precision: 5μ;

5.Input power: 380V/50HZ/3Phase or 220V/60HZ/3Phase;

6.Rotation speed: 0~4000RPM;

7.Oil tank capacity: 60L;

8.Flywheel inertia’s moment: 0.8KG.M2;

9.Center height: 125MM;

10.Output power: 11KW;

11.Overall dimension(MM): 1900×800×1550;

12.Weight: 800 KG.

We professional supply common rail parts for 10 years, more than 2000 kinds of model number in stock.

more details, please contact me.

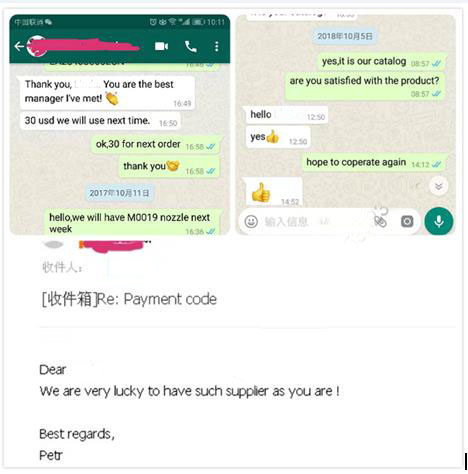

Our products have been sold to many countries,welcome by customers.

Our product's quality is tested by lots of customers, please rest assured to order.

The CRS-618C high-pressure common rail test bench is the latest integrated equipment developed by our company to test the performance of high-pressure common rail pumps and injectors. It can test the performance of various manufacturers’(BOSCH, DENSO, DELPHI, SIEMENS, CAT) pumps and injectors as well as piezoelectric injectors. This equipment completely simulates the principle of the injection system of a high-pressure common rail engine. The main drive adopts advanced frequency conversion speed regulation technology, with large output torque and ultra-low noise. The common rail pump and injector are tested using imported flow sensors, and the test speed is fast, the measurement is more accurate and stable; it can be grafted with EUI/EUP system, and can detect the CAT 320D common rail pump. The oil pump speed, injection pulse width, oil volume, and rail pressure of the test bench are all controlled by an industrial computer in real time to collect data. The 19″ LCD screen displays more clearly, with more than 4,000 kinds of built-in debugging data that can be queried and printed (optional). The work is reliable and stable, and the control accuracy is high. The shell is processed and manufactured by CNC equipment, which is beautiful and durable.

The CRS-618C high-pressure common rail test bench is the latest integrated equipment developed by our company to test the performance of high-pressure common rail pumps and injectors. It can test the performance of various manufacturers’(BOSCH, DENSO, DELPHI, SIEMENS, CAT) pumps and injectors as well as piezoelectric injectors. This equipment completely simulates the principle of the injection system of a high-pressure common rail engine. The main drive adopts advanced frequency conversion speed regulation technology, with large output torque and ultra-low noise. The common rail pump and injector are tested using imported flow sensors, and the test speed is fast, the measurement is more accurate and stable; it can be grafted with EUI/EUP system, and can detect the CAT 320D common rail pump. The oil pump speed, injection pulse width, oil volume, and rail pressure of the test bench are all controlled by an industrial computer in real time to collect data. The 19″ LCD screen displays more clearly, with more than 4,000 kinds of built-in debugging data that can be queried and printed (optional). The work is reliable and stable, and the control accuracy is high. The shell is processed and manufactured by CNC equipment, which is beautiful and durable.

This equipment can realize remote diagnosis of faults, making maintenance faster and more convenient.

-

original fuel injector 0445120236 5263308 PC350-7

-

UD brand valve F00VC01349 for injector 04451102...

-

genuine orifice valve plate 06#/19# for diesel ...

-

2019 China New Design Original New Injector 044...

-

delphi original nozzle L216PBC for 21371672 213...

-

泵-300x300.jpg)

GENUINE STANADYNE/JOHN DEERE ROTARY DIESEL FUEL...